Equipment introduction

The thawing machine is composed of a frame, a three-layer meshbelt, a built-in mixed gas pipe, a Roots blower, a built-in injectionpipe, a PLC control cabinet, and an RV reducer. The steam outputcan be controlled separately; the cold air circulation is in the internalcirculation mode, and the compressed air of the blower is in theinternal circulation mode; PLC can set menus such as: menu 1 bulkduck wings, menu 2 duck necks, etc. to realize one-key start andonline adjustment.

The material enters a mesh belt of the thawing machine, and thespray tube is blown up and down, and acts on the surface of theproduct at a speed of about 3 meters per second. Since thetemperature of the product is minus 18o and the surface is an icelayer, the spraying gas can be appropriately increased. Thetemperature causes the surface of the product to frost, and the solidice between the objects loosens. When falling into the second floor,the material will be scattered by the drop. During the operation of thesecond floor, the temperature of the jet gas can be appropriatelylowered and will be dispersed. The product is frosted at thedisconnected interface, which exposes the internal flesh andproduces condensed water when the product runs at the end of thesecond layer. The temperature of the sprayed gas on the third-layermesh belt is lowered, and combined with the internal cold aircirculation of the built-in air cooler, the use of similar, Defrosting ata relatively low temperature to prevent overheating and discolorationof the product surface. The entire thawing process takes about 30minutes, and adjustments can be made according to differentproducts.

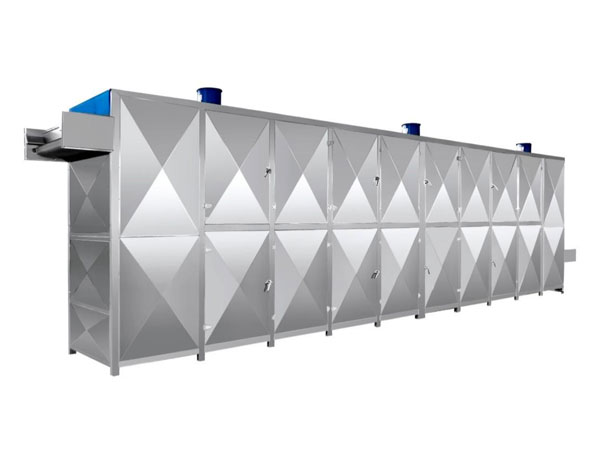

High humidity low temperature defrosting machine

High humidity low temperature defrosting machine

Continuous low temperature and high humidity thawing

Continuous low temperature and high humidity thawing

Vacuum cooler

Vacuum cooler

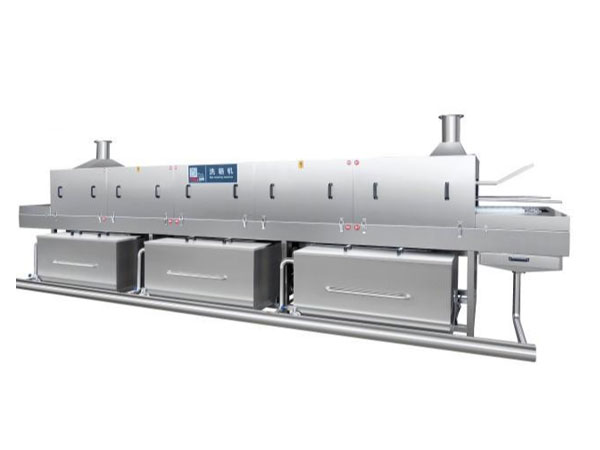

Cleaning equipment series

Cleaning equipment series

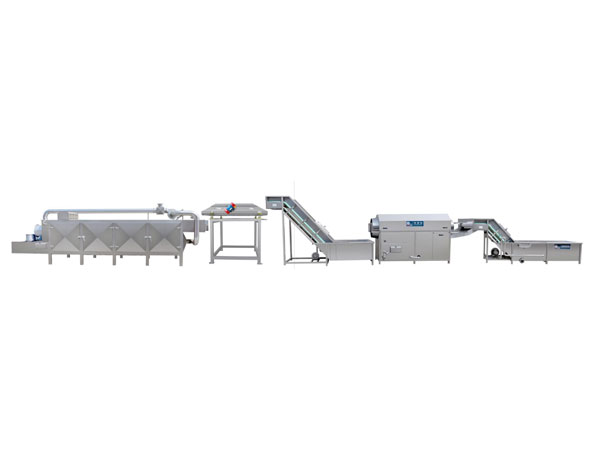

Automatic pasteurization line

Automatic pasteurization line

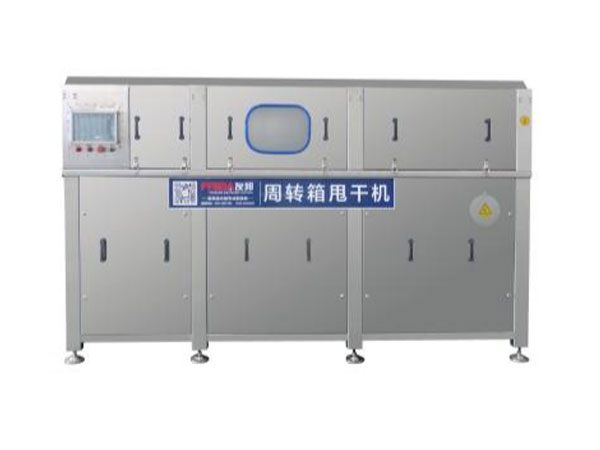

Automatic washing,conveying and dryingmachine for crates

Automatic washing,conveying and dryingmachine for crates

Conveyor

Conveyor

Automatic marinating line

Automatic marinating line

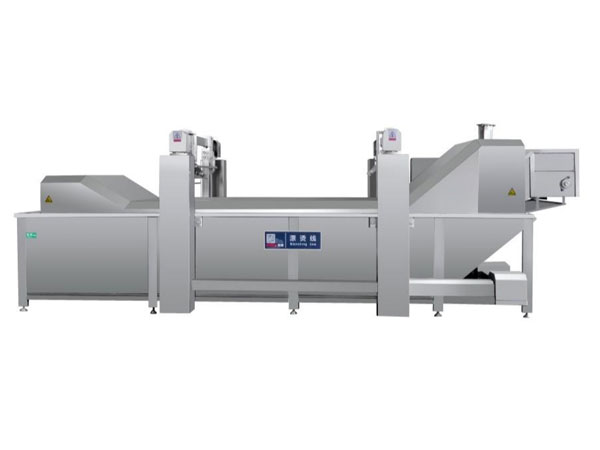

Cooking and blanching line

Cooking and blanching line

Washing and drying line for packaged food

Washing and drying line for packaged food

Air dryer

Air dryer

Hot air dryer

Hot air dryer

Airenergy dryer

Airenergy dryer

Bottle cleaning machine

Bottle cleaning machine

Sausage rod cleaning machine

Sausage rod cleaning machine

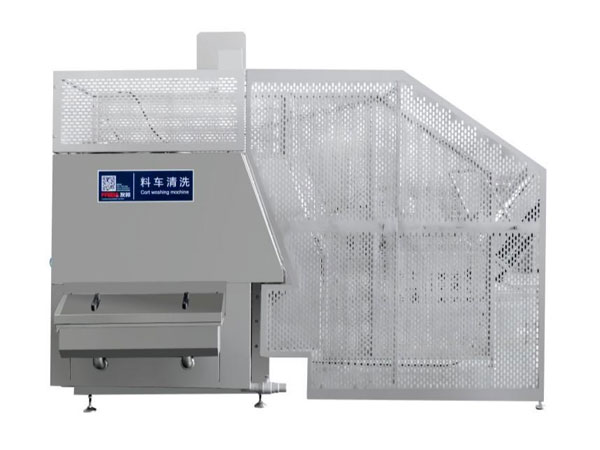

Cart washing machine

Cart washing machine

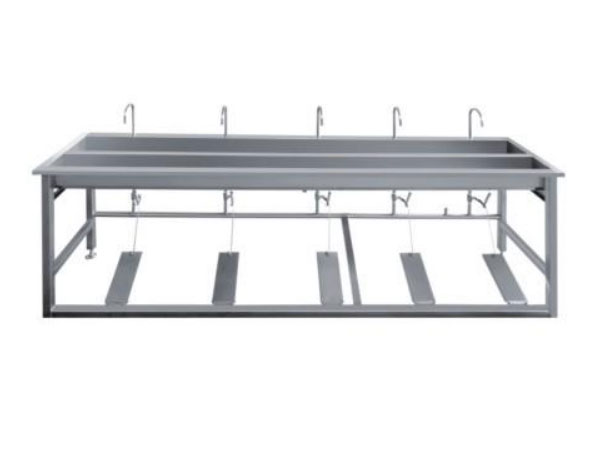

Auxiliary equipment

Auxiliary equipment